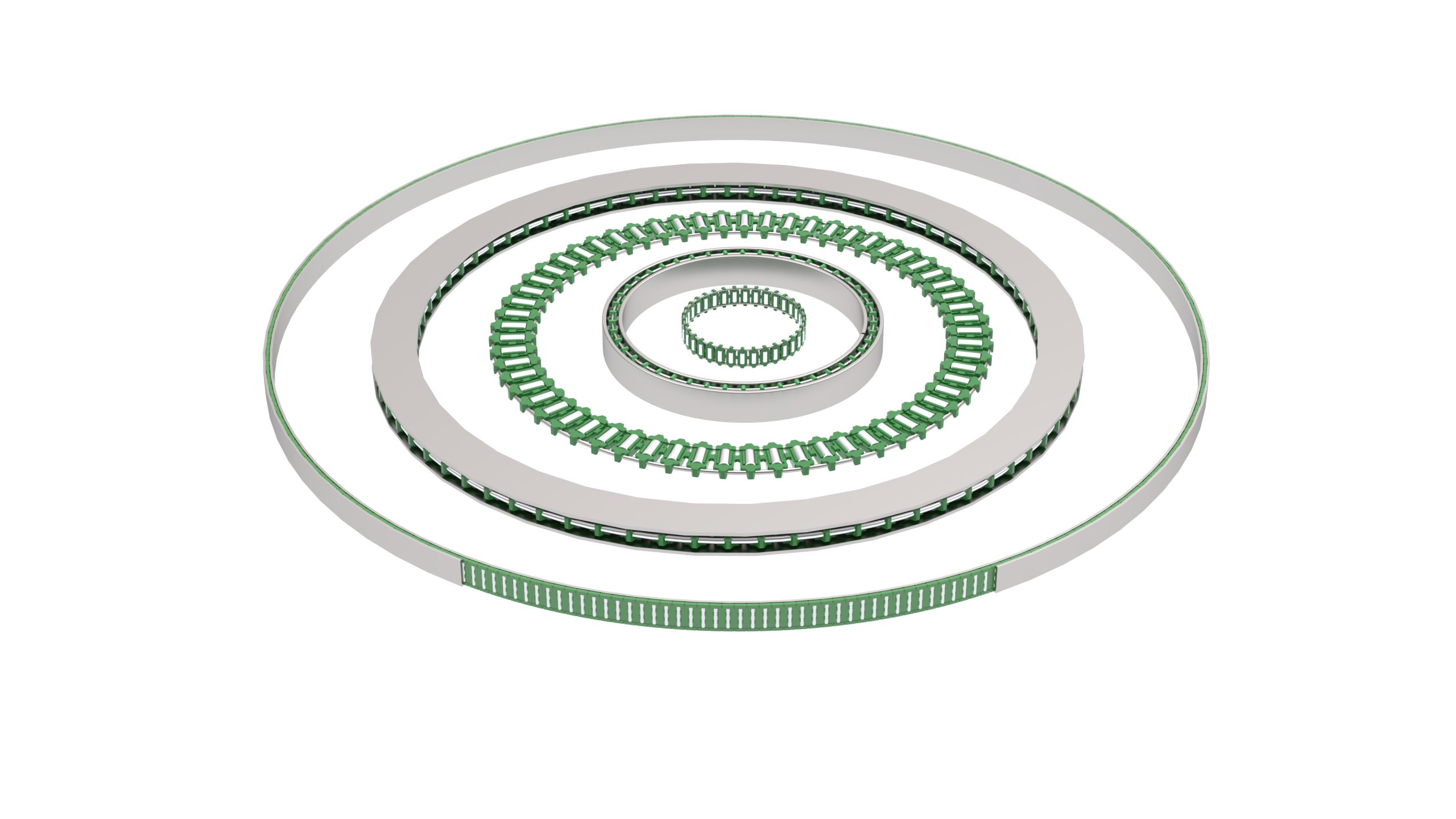

Axial and radial bearing elements

The axial-radial roller bearings are heavy-duty, very rigid and accurate bearings used for the bearing support of ball screws in machine tools. They are directional in all axes of rotation: axial, radial and diagonal.

Axial and radial bearing elements

Axial and Radial bearinglements

Design: glass fibre reinforced thermoplastic Grivory

Design: glass fibre reinforced thermoplastic Grivory

Design: glass fibre reinforced thermoplastic Grivory

Technical description

KMF angular contact ball bearings of type series SKE are low-friction, ready-to-fit installation elements with high accuracy for high speeds, high axial and radial load carrying capacity and high tilting rigidity. SKE insert elements have raceways arranged at an angle of 45° to the bearing axis. The bearing rings are slotted. The KMF angular contact ball bearing insert element SKE consists of 2 hardened ball races with ground or machined raceways and ball cage (closed) with guided and retained balls. Ball races are made of hardened rolling bearing steel hardness 60-63 HRC , ball cage (composite construction) polyamide PA 12 with carrier body made of steel, balls DIN 5401 hardened rolling bearing steel 100 Cr6 hardness 59 ÷ 65 HRC / grade 10. Limiting temperatures of the bearing are -40°C and +100°C in continuous operation, +120°C in short time operation.