Wire Race Ball Bearings - Fixtures

The term wire race ball bearingrefers to a rolling bearing whosewhose raceway consists of hardened wires. The running surfaces are produced as a forged ball racewayground or profile drawn.

Wire Race Ball Bearings - Fixtures

The term wire race ball bearingrefers to a rolling bearing whosewhose raceway consists of hardened wires. The running surfaces are produced as a forged ball racewayground or profile drawn.

Wire Race Ball Bearings - Built-In Elements

The term wire race ball bearingrefers to a rolling bearing whosewhose raceway consists of hardened wires. The running surfaces are produced as a forged ball racewayground or profile drawn. The various wire/ball combinations allow a large number of differentof the most diverse installation forms. What all wire products have in common wire productsthat they offer economical solutions to conventional rolling bearings, even in problem areas. The production is carried out at KMF Kunststoff-Metall-Formteile to the highest standards of precision and quality..

Small installation space

High static and dynamic load capacity

high precision

long service life

light weight and short delivery time

GENERAL Information

Download

Wire Race Ball Bearing -Track Drawn

Download

Wire-race ball bearing

Download

Calculation examples

Download

Accessories

Download

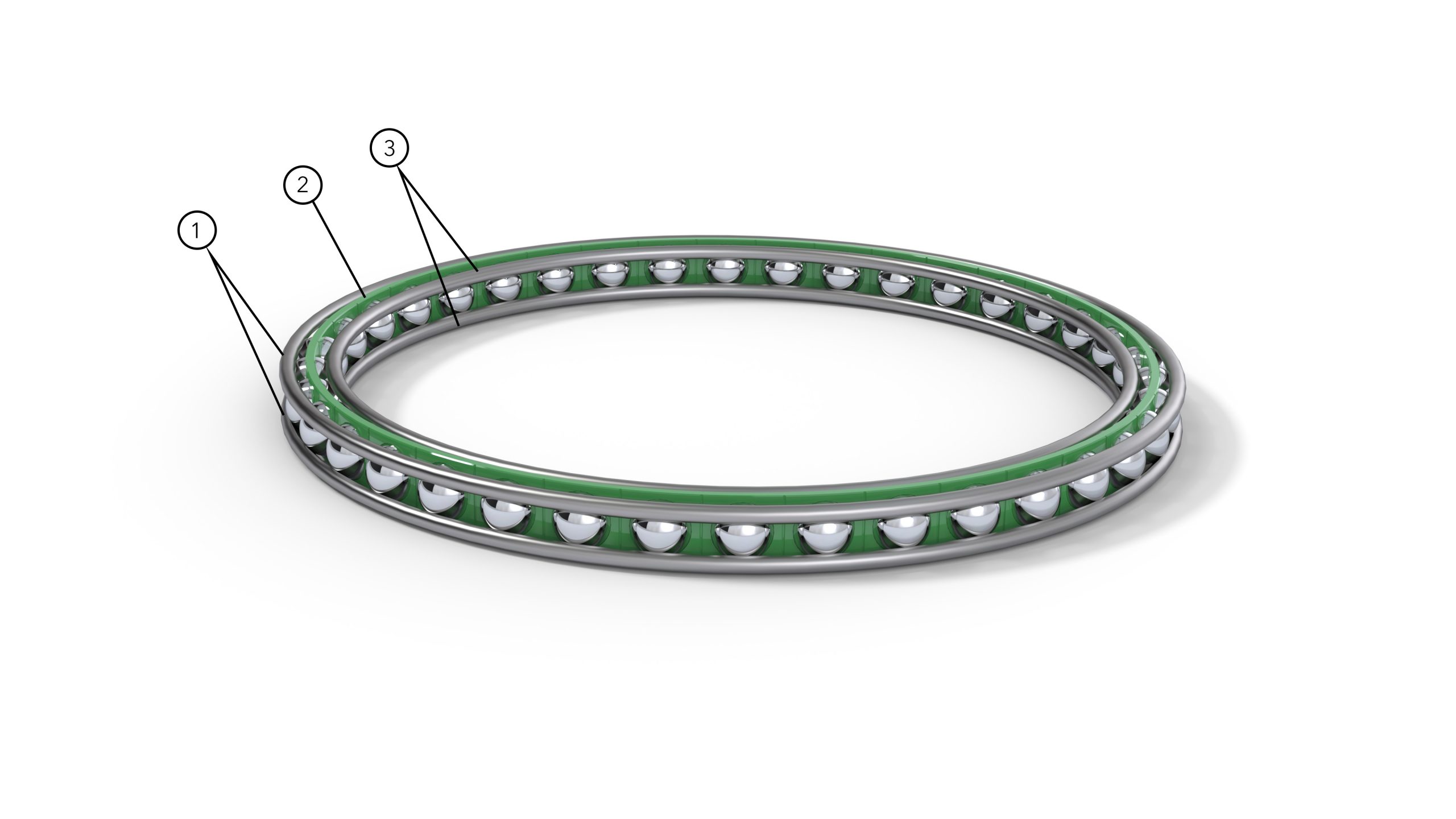

individual constituents

1. two ball races - outside

With ground or drawn, forged raceways

2. a ball treadmill with balls

Balls guided and held

3. two ball races - inside

With ground or drawn, forged raceways

Technical description

BUILDING DESIGN DESCRIPTION

KMF wire race ball bearing elements are used in allused wherever there is insufficient space for a complete for a complete bearing. The wireball bearing has become more and more widespread in recent years, since the machine construction can beconstruction can be designed with almost no regard for thebearing required. A cleanly turned groove with easy to maintain groove with tolerences in the customer's design that are easy totances in the customer's design.

This design makes it possible to dispense with the conventional support rings (as rings (which are provided for a complete bearing). dispensed with. The customer thus receives not only a space-saving, but also an extremely cost-effective bearing. We achieve the long service life of our wire race ballball bearing elements by using through-hardened running wires with a raceway that matches the ball diameter.raceway corresponding to the ball diameter. The 90° contact angle of the bearing enables the radial and axial forces and moments from any direction.and axial forces as well as moments from any direction.

Range of application

The limiting temperatures of the bearings in the standard version arebearings are -40°C and +100°C in continuous operation and +100°C, in short-time operation at +120°C.