Linear Bearing Cages

Linear Bearing Cages

Linear bearing cages

improved running characteristics

Suitability of plastic composite cages

corrosion resistant and resistant

high cost reduction

Linear bearing cage ball cage

Download

Linear bearing cage roller cage

Download

Linear bearing cage - special

Download

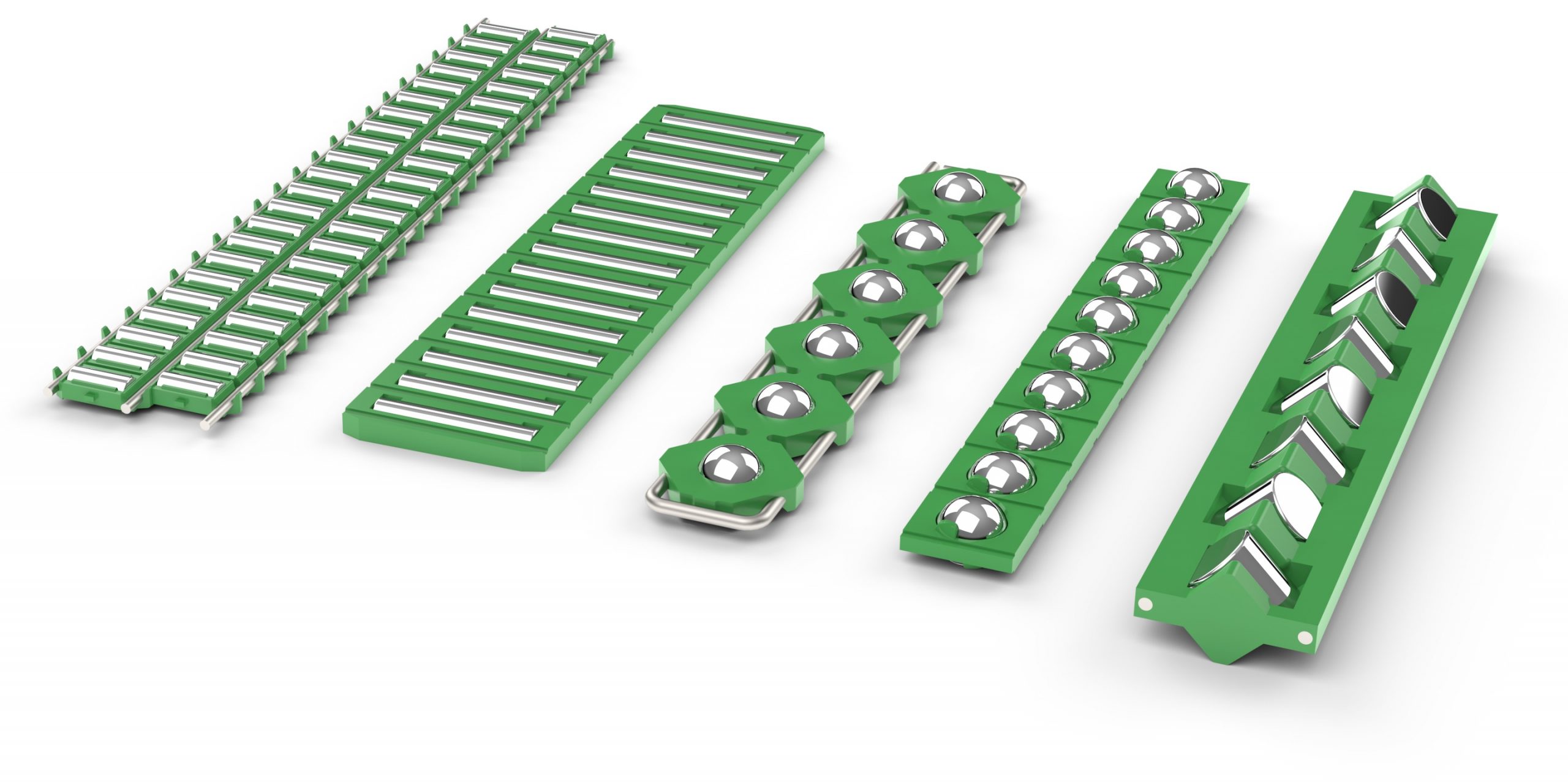

Linear bearing cage ball cage

Linear ball cages of the type series KKLK, KKVK, KKAK and KKNK are pure plastic cage bands which have been taken over for the most part from the standard program - rolling bearing cages - for the linear range. The cage tapes are produced in meter goods and are specially manufactured for linear applications by means of a separate annealing process to stretched lengths. Ball cages of the type series have ball pockets with rolling element guide and retainer. They are offered including balls as yard goods or cut to length ready for installation. The standard ball for filled linear ball cages is made of the material 100Cr6 according to DIN 5401 / Grade 15 (Class 2). Variants made of other materials such as corrosion-resistant steel (X46Cr13 / 1.4034) or plastic (POM) and ceramic (AL2O3) are also possible.

Linear bearing cage roller cage

Linear roller cages of the KKXL, KKBN, KLBF, KKFF, KKHW series are plastic cages guided by rolling elements. The roller pockets have a rolling element retainer. The cages are produced in a limited manufacturing length (HLG) and are therefore not available by the meter. They are supplied without rollers with a minimum order quantity of 100. Rollers can be supplied separately. Linear bearing cages with limited manufacturing length are produced in POM (polyacetal) material. The main thermal properties are dimensional stability 105°C and linear coefficient of thermal expansion 10.4 x 10-5 determined in a temperature range from -40°C to 30°C. The complete material characteristics mechanical, thermal and electrical properties, on request.

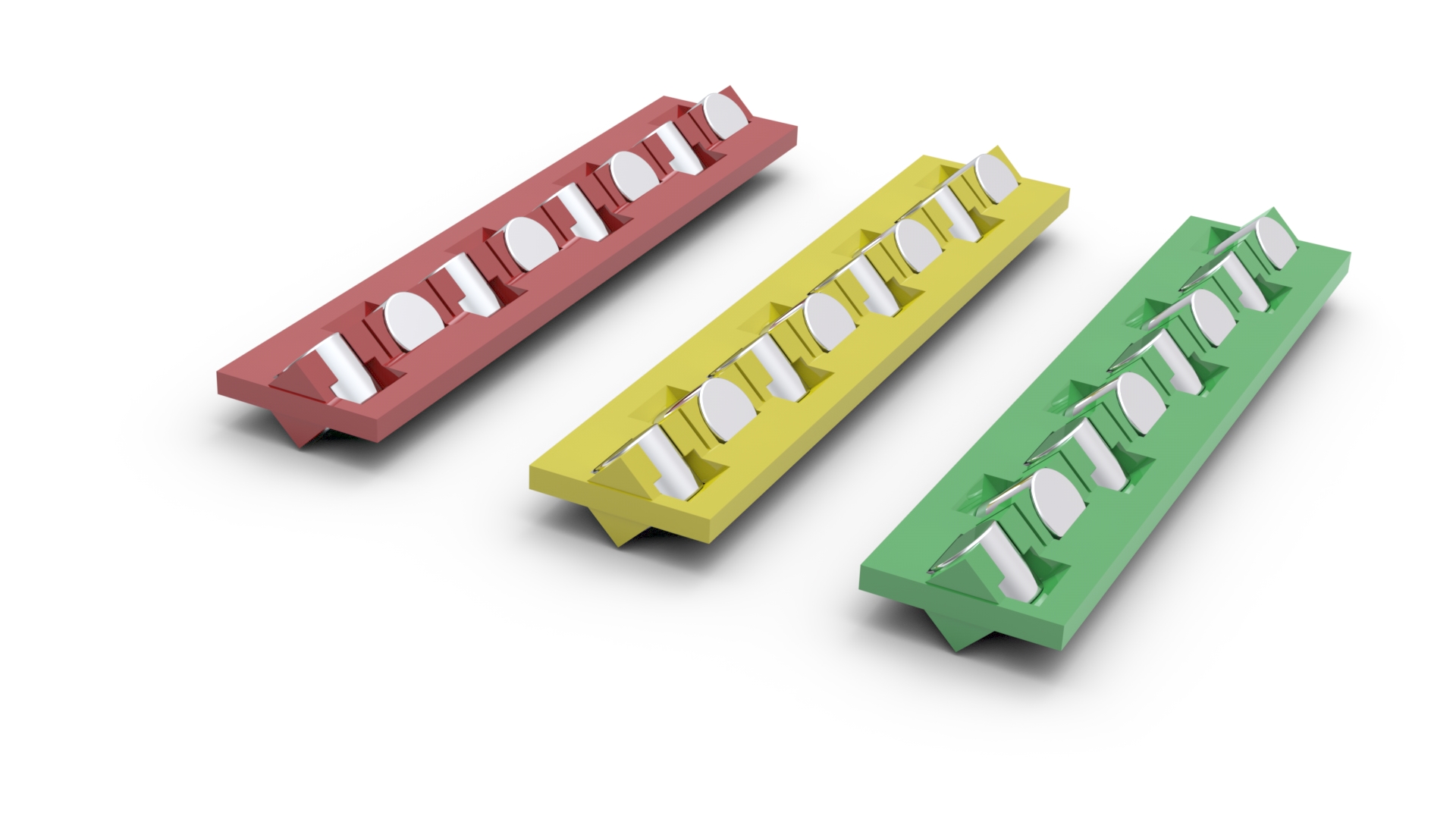

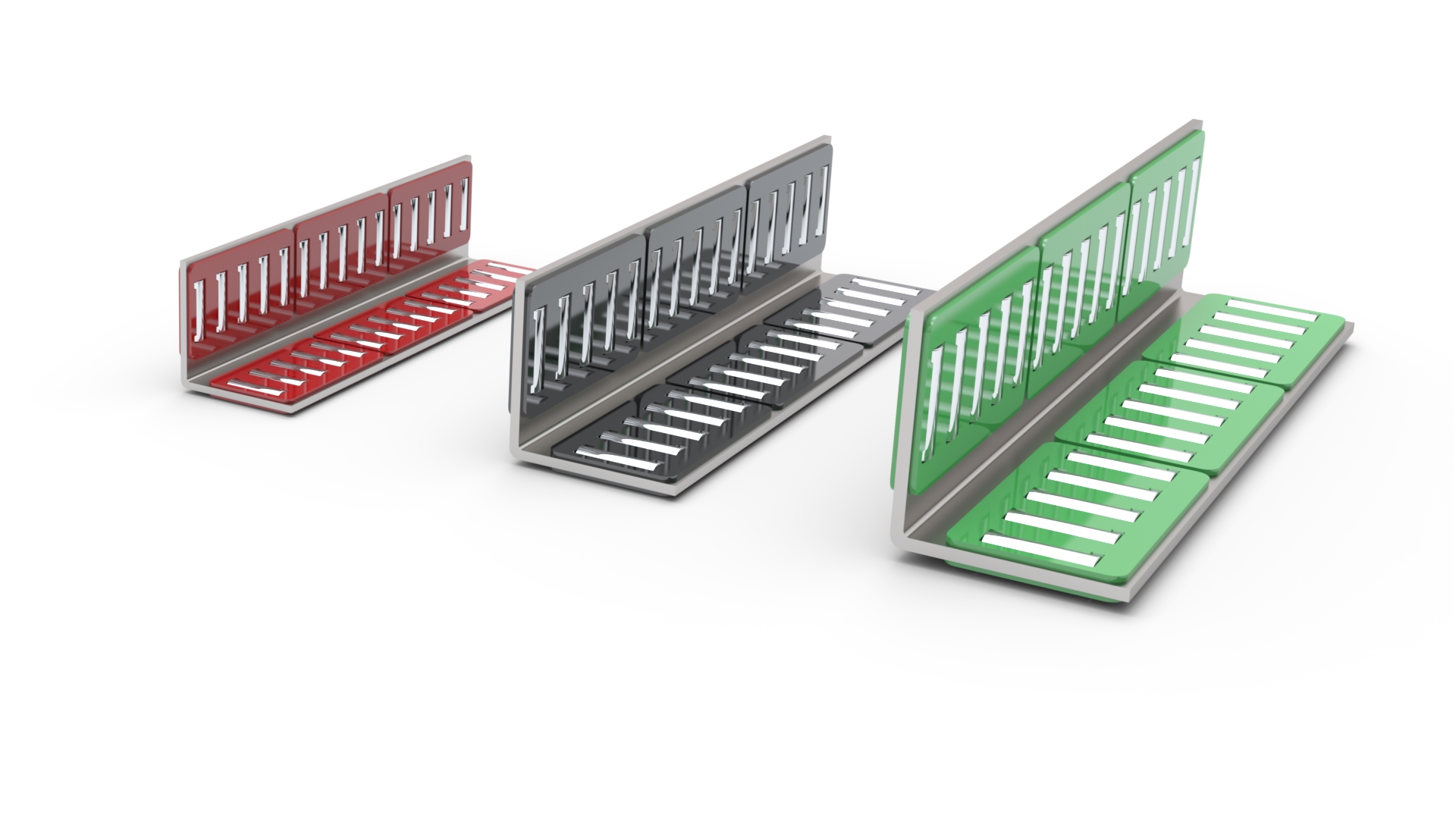

Linear bearing cage - special

Linear bearing cages type KKLR are double-row needle roller and cage assemblies made of plastic. The cage bands are manufactured by the meter, and have rolling element supports. The legs of the two rows of barrels can be easily bent to any angle (preferably 90°) due to the special shape of the middle section. By separating the two rows of races, single-row flat cages can be realized by the meter. The angled flat cages shown are customer-specific KMF developments. They are therefore not available in the standard program and enjoy customer protection. KMF will name suitable sources of supply or provide information on possible alternatives on request.